Product List

Contact Us

Contact:Mr.Ren

Phone :0086-13256626826

0086-535-6896668

Fax :0086-535-6896668

E-mail :271225082@qq.com

Website:http://en.ytxingjian.com/

0086-535-6896668

Current Location: Home > Product > Two-Roller Barrling Machine >

JY series of two rolls of high-precision barreling straight unit is mainly used for preciously straightening and burnishing peeled or grinded metal bars as well as black material and precision round forged steel, and it has high efficiency.

The unit features are: practical applicability, processing stability, fast speed, good surface quality and high machining accuracy. The range of work is from Φ12mm to the Φ160mm covering the entire section and the new section and servo automatic control are under development.

The unit is divided into A and B types. Type A is of framed structure, to eliminate the gap hydraulically , and designed with hydraulic overload protection system with high straightening precision. Type B is two- beam and four-post one to eliminate the gap mechanically. The processed bar surface has good quality and high precision.

JDW series is developed for the larger round, square, hexagonal steel, which is equipped with loading, feeding, turning and discharging mechanism; its horizontal structural design is reasonable with large straightening range and steady operation. The development of the machine greatly reduces the operator's labor intensity and improves production efficiency

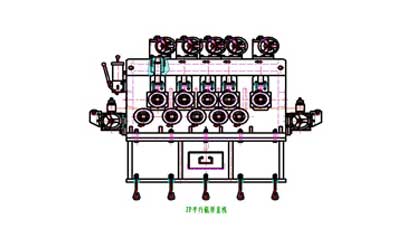

JP series parallel roller straightening machine is designed for general-type of section bar straitening, replacement of a different type of roller for straightening different section bar. The design of different roller spacing is more rational to further improve processing quality.

The design of JX series multi-roller straightening machine with reference to the prototype advantages of major foreign companies, combined with the production characteristics of the domestic enterprises, is optimized and practical. The model includes six -roller, seven- roller, 10- roller and so on. It is mainly used for the straightening of hot rolling, annealing and cold-rolled bar, drawing and welded pipe. It has features of stable and reliable operation, high efficiency and good surface quality. The features of straightening all-round bending material and preventing the emergence of the spiral curved make the device advantages more obvious.

The straightening machine is an equipment to straighten metal bar, tube and wire. The machine change bar straightness by extrusion of straightening rollers. Generally, there are two rows of straightening rollers, the numbers of roller is different. There are also two-roller straightening machine, straightening different diameters of material depending on the change in the angle of two-roller (middle concave, hyperbolic roller). The main types include pressure, balance roller, shoe roller , rotary anti-inflection straightening machine, and so on.

Straightening Machine Application: mainly used for straightening the heat- treated metal piece. Types of straightening machine consist of hydraulic, steel pipe , automatic, shaft, steel bar steel wire, tube bar straightening machines and other. Shaft automatic straightening machine is designed for bending deformation of heat –treated shaft products with automatic detection the alignment device, and its excellent technical performance is embodied in the advantages of high accuracy, fast production speed and wide adaptability. The main function of the tube bar straightening machine is to straighten the curvature of the non-ferrous pipe and bar and to improve the surface roughness and cross-section ovality; applying to straighten straight-line pipe of the electrical heated tube industry. Semi-automatic straightening machine can process different diameters of round steel, start cycle working as straightening. At the end of one cycle, sound and optical alarm reminds the operator to proceed to the next cycle.

-

JY120 Two-Roller Barrling

JY120 two-roll rolling barrelin...[Product Details] -

JDW series

JDW series is developed for the...[Product Details] -

JP series parallel roller

JP series parallel roller strai...[Product Details]